We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

This page is a guideline ONLY. Please consult a professional

Introduction

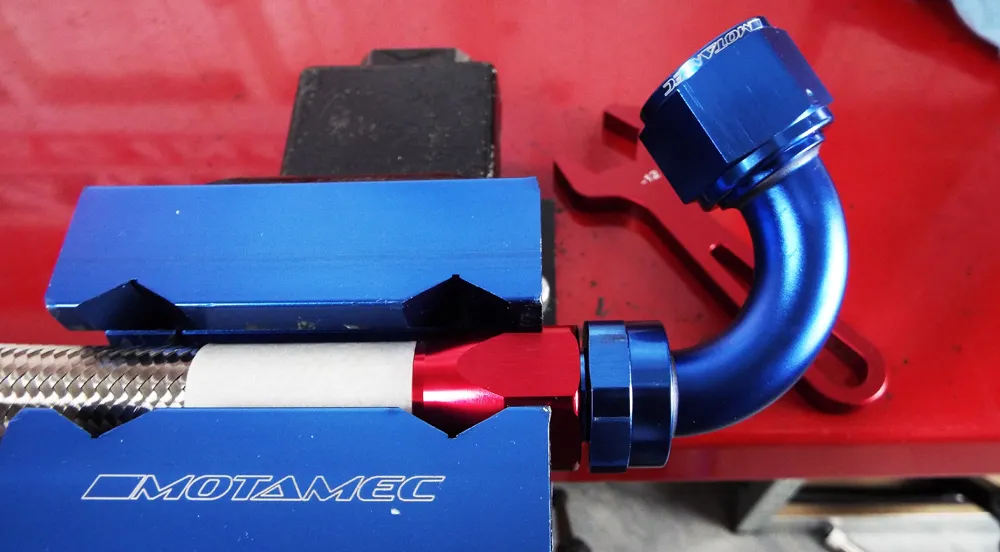

In this 'how to' we will show you how to put together some stainless steel braided hose and alloy fitting. In this case we will be using a -12AN/JIC fitting and hose, but the same method will work on fittings and hose of other sizes.

The tools you will need are:

- Bench Mounted Vise.

- Motamec Vise Jaws.

- Motamec -12AN/JIC Alloy Spanner

- Small tip flat head screwdriver

- Pliers

- A Fine Tooth Hand Saw

- Some lubricant

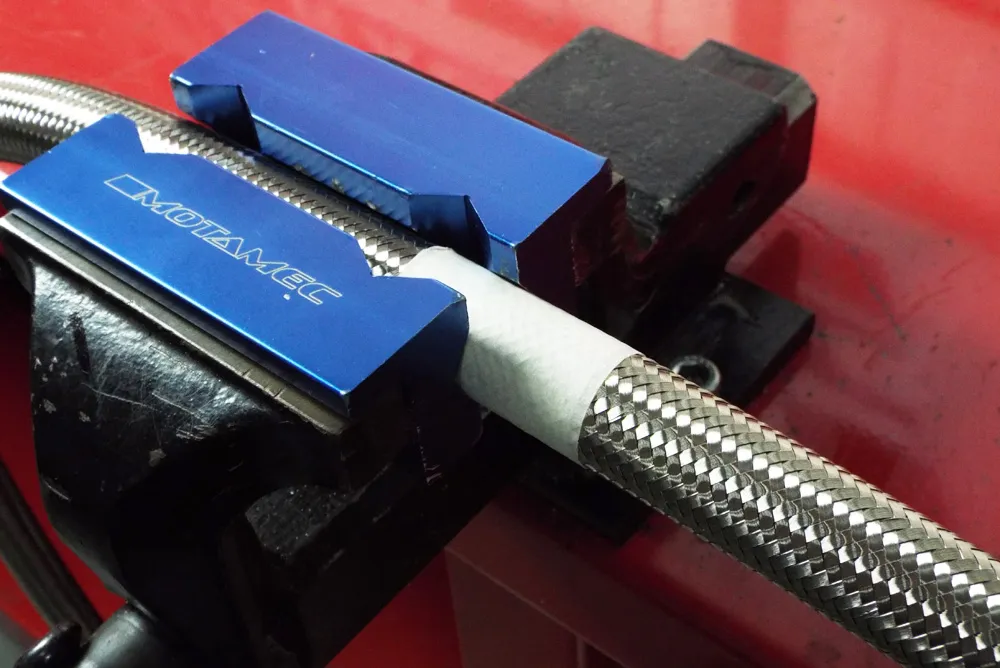

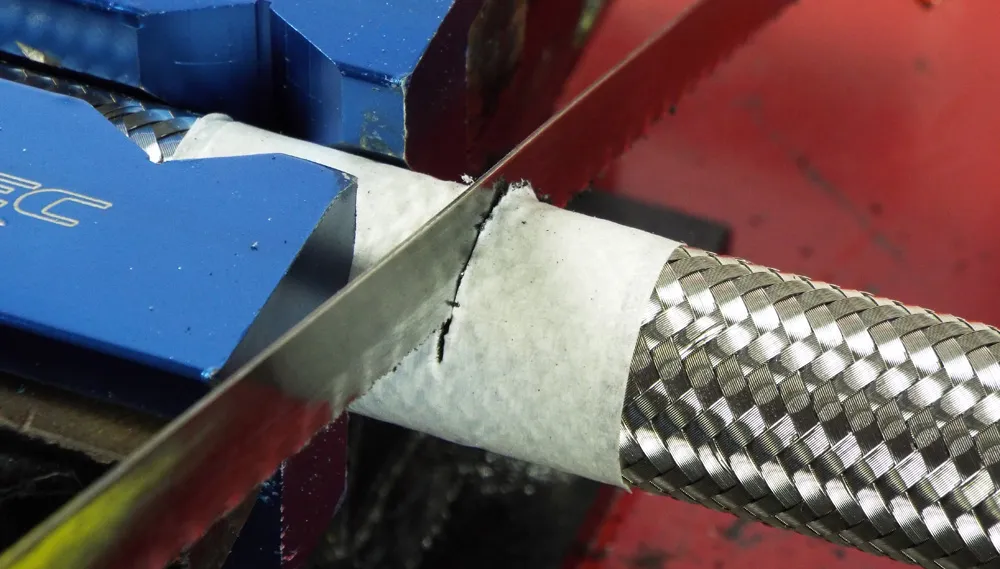

Measure Twice Cut Once

Measure the amount of hose you want and then cut it. With this thickness of hose we recommend using a fine tooth saw and taping up the area you want to cut with masking tape. This will help reduce fraying on the stainless steel braid. As its very important to have a very clean and straight cut.

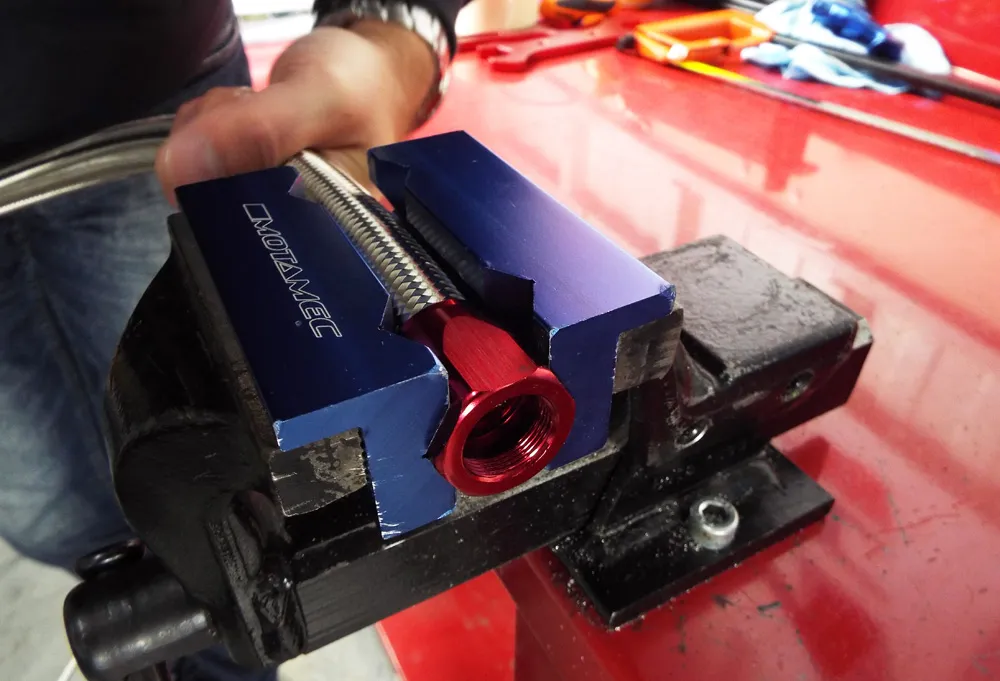

Inserting the Hose into the Fitting

REMOVE THE MASKING TAPE.

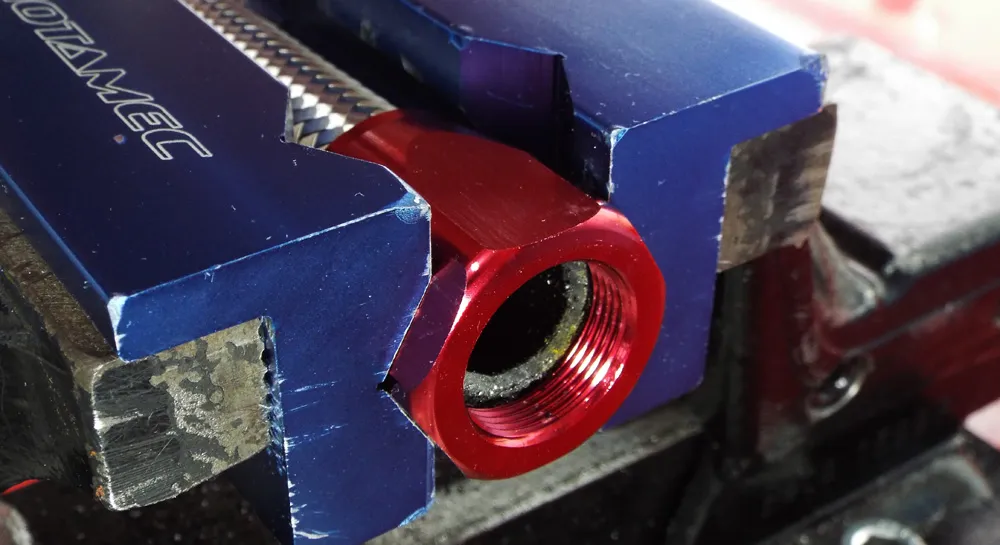

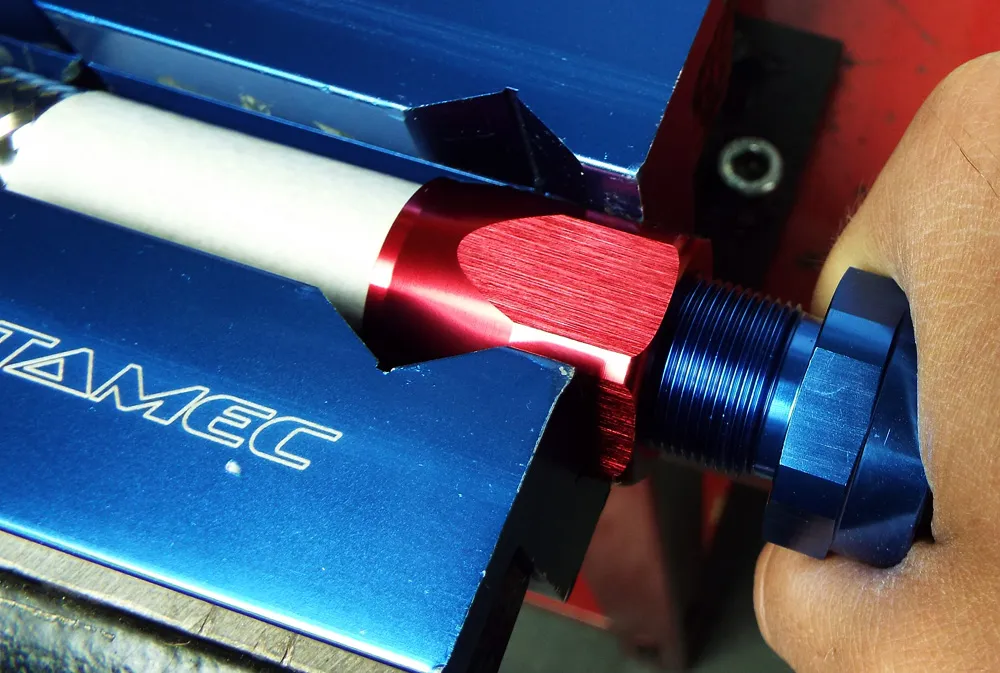

Now we unscrew the hose end of our fitting. Then using a twisting motion push the hose into the back of the red part of the fitting. Once you've got it started off we recommend placing it in a vise. Keep pushing the hose into the fitting until the end of the hose is secured against the step inside the hose end.

Tightening the Fitting

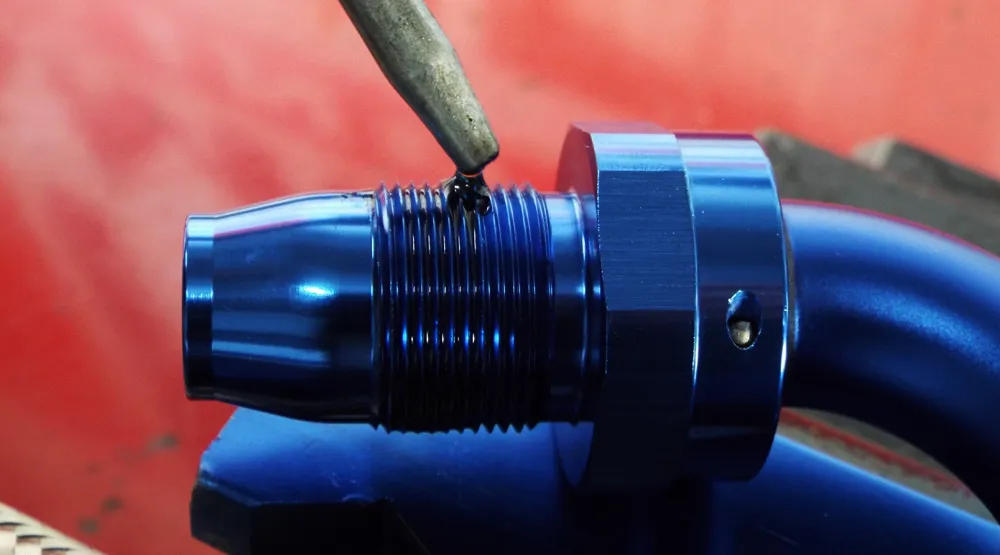

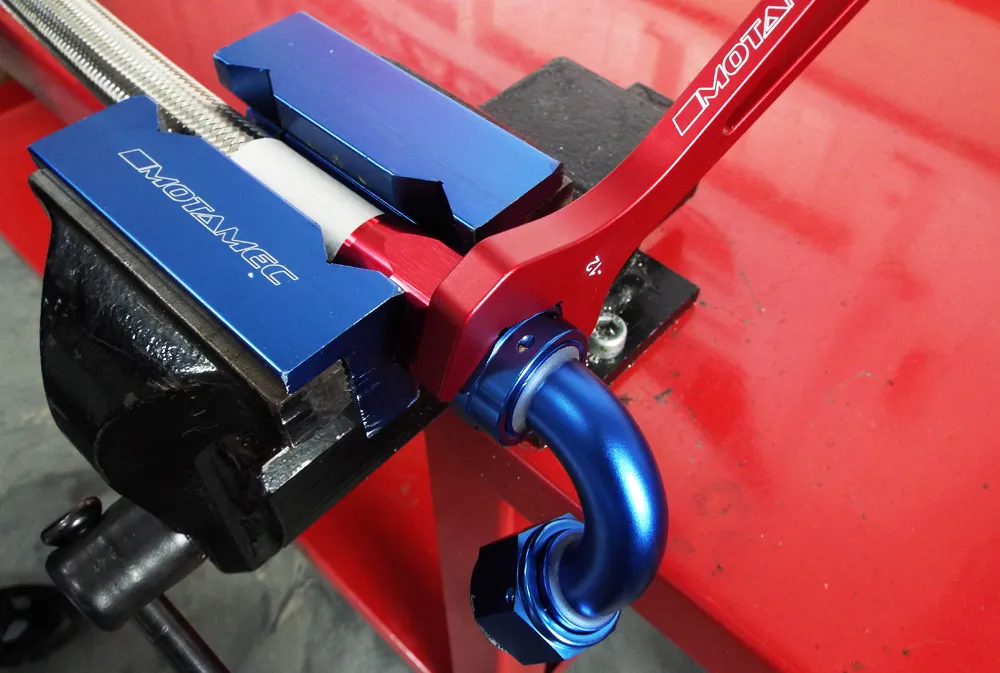

We have put some more masking tape on the exposed part of the hose. This is IMPORTANT, so we can see if the hose moves when we tightten it up at the next step. Next you should lubricate the thread on the fitting. Then using your hands insert the ftting into the hose end and get it started on the threads. Once this starts to become tight use a AN spanner to tightten the fitting up.

The Finished Hose

The first picture below shows our finished hose with a small gap remaining. Also the masking tape shows us that the hose didnt move, we can now remove that masking tape. Finally we can use our hose and fitting for its intended purpose on an oil cooler. When connecting to an oil cooler do not exceed 35Nm of torque.